- +55 (12) 3932-2300

- [email protected]

Blog

Discover in this article a pressurized system solution applied to companies that constantly pump water and fluids.

Negative pressure free water supply equipment is a type of pressurized water supply unit that is directly connected to municipal mains water supply. Allows overpressure water supply based on the pressure of the municipal water supply network to ensure that the pressure in the municipality's network is not lower than the set value.

Where is the Pressure System applied?

High water supply for residential buildings, communities, towns, hotels, office buildings and shopping malls. Transformation of old reservoirs and other forms of water supply. Circulation systems and lifting stations in hydraulic systems.

Free negative pressure, variable frequency and constant pressure water supply equipment.

Process

When the flow in the municipal network supply is greater than the water consumption, the system is supplied by flow with variable frequency and constant pressure. At this point, a certain amount of confined water is stored in the constant flow tank. When the pressure at the junction of the municipal mains and the constant flow tank decreases to relative 0 or below due to increased water consumption, negative pressure is built up in the tank, and the vacuum suppressor inlet valve opens to let in air. At this time, the flow tank is acting as an open water tank with a free surface, with the same pressure as atmosphere, thus eliminating the negative pressure. When the level drops to the set value, the system control on the variable frequency panel receives the level signal and stops the pressurizing unit, as a result, the water supply is interrupted; When water consumption decreases, the level in the flow tank constant rises, air is discharged from the exhaust via a valve, the pressure is back to normal, and the pressurization unit automatically restarts the result is that the water supply is restored.

Delta solution

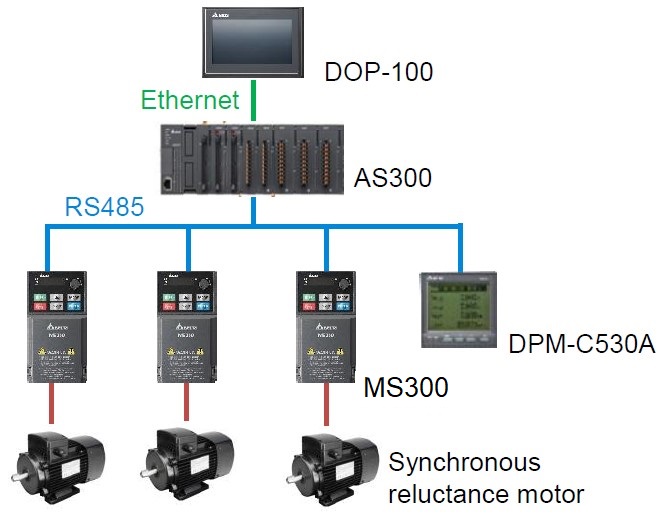

Below is the solution architecture, consisting of 3 series inverters MS300 for pressure control through the PID function incorporated in inverters, in addition to having multi power meters of the DPM series and the control system with the PLC AS300 and graphical interface DOP-100.

List of Materials

| TYPE | Description | Delta code | The amount |

| HMI | Monitoring and parameterization system | DOP-110WS | 1 |

| CLP | Data Collector and Logic Execution | AS320P-B | 1 |

| INVERTER | Pump control | VFD2A7MS43ANSAA | 3 |

| ENERGY METER | Monitoring of electrical quantities | DPM-C530A | 1 |

| MOTOR PUMP | Synchronous water pump | MSI11C-30CDXS2D1A | 3 |

| PRESSURE SENSOR | pressure detection | AT | 2 |

Features and Benefits

Intelligent constant pressure water supply control for more stable output pressure

- Variable frequency control and intelligent increase/decrease of the number of pumps to avoid pressure fluctuations and keep the water pressure stable.

- Water supply by pressure division. Automatic adjustment of desired supply pressure to meet supply demands at different times.

Dedicated Pump Functions to Improve Efficiency and Reliability.

- Uniform frequency and control to balance pump load for efficient pump operation.

- Sleep/wake function to avoid frequent starts/stops due to small flow.

- Reliable negative pressure detection, constant pressure flow tank and water shortage to avoid pump empty.

Efficient synchronous reluctance motor to save energy.

- The synchronous reluctance motor offers energy efficiency up to IE5, combined with variable frequency control to save energy.

Translated document Luis Cristofoli from the partner company Automation in Cascavel

Fill out the form and receive our updates directly to your email

Address

São José dos Campos

Estrada Velha Rio-São Paulo, 5300

Eugênio de Melo | São José dos Campos

CEP: 12247-004 | SP - Brazil