- +55 (12) 3932-2300

- marketing.br@deltaww.com

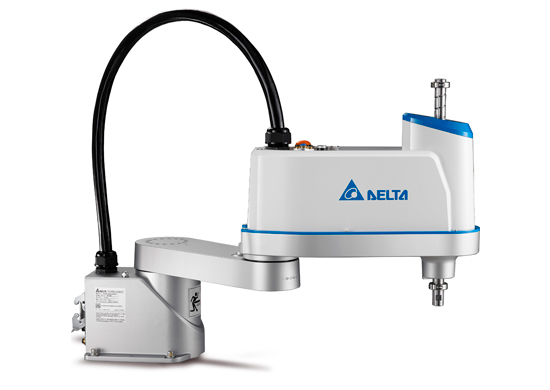

Robô SCARA

- Robôs Industriais

Descrição

Robô SCARA: desenvolvido para aplicações industriais que requeiram Alta Velocidade e Alta Precisão

Os processos de fabricação na indústria eletrônica, por exemplo, têm que ser executados de forma rápida e precisa garantir produtividade e qualidade. O robô SCARA (“Selective Compliance Assembly Robot Arm”, ou “Braço Robótico para Montagem de Conformidade Seletiva”) da Delta é a melhor opção para reduzir o custo do trabalho e possibilitar a flexibilidade de fabricação.

O Robô SCARA Delta possui funções de controle que possibilitam excelente velocidade, linearidade e verticalidade e repetibilidade para executar rapidamente e com precisão tarefas de operação, tais como inserção, montagem, parafuso de travamento, carga e descarga, pick-and-place, empilhamento e embalagem. Com a ajuda dos Sistemas de Visão da Delta, o Robô SCARA pode realizar identificação inteligente, inspeção e classificação para reduzir efetivamente as taxas de defeitos, garantindo a qualidade dos produtos de forma consistente.

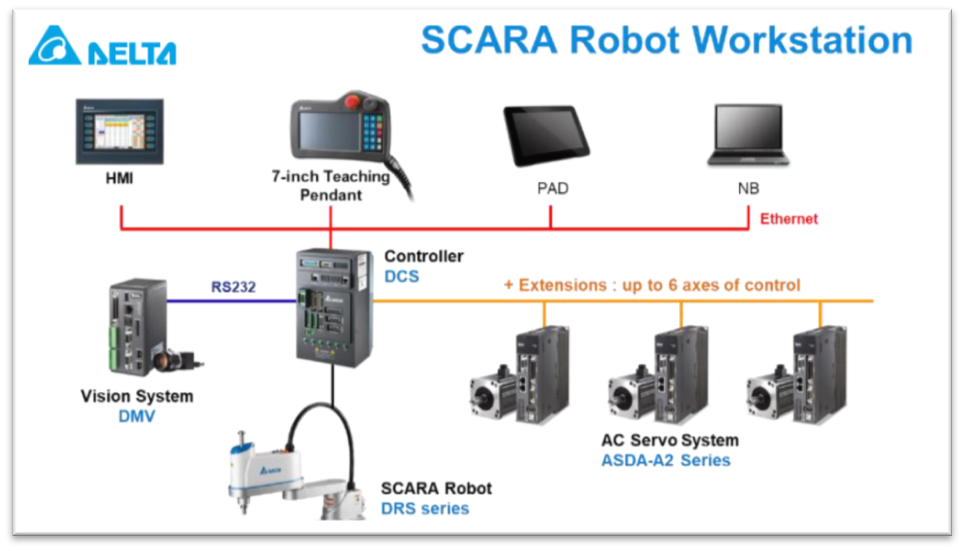

Quando combinado com unidades de controle e outros dispositivos periféricos, como servo sistemas, sistemas de visão e módulos lineares, o Robô SCARA Delta se torna uma estação de trabalho robotizada altamente integrada para uma ampla gama de indústrias, incluindo eletroeletrônicos, borracha e plástico, fabricação de metal e para processos como acionamento de parafusos, distribuição, montagem, carga e descarga, soldagem, transporte e embalagem.

Projetados para operar em ambientes perigosos, podem ajudar a atingir objetivo de uma manufatura flexível, reduzir a mão de obra e economizar tempo de desenvolvimento.

Módulo Controlador

O Módulo Controlador do Robô SCARA Delta, conhecido como Série DCS, fornece eixos de extensão para controle de movimento através servo-drives, módulos DI/O e conexão de dispositivos periféricos via DMCNET, rede de alta velocidade para comunicação em tempo real da Delta, para atender a todos os tipos de aplicações industriais. Além disso, o DCS também suporta a interface MODBUS/TCP para conectar dispositivos periféricos, incluindo sistemas de visão de máquina, sensores, controladores de host e computadores para um sistema de automação robótico completo.

Série DCS – Controlador do Robô SCARA da Delta

Arquitetura típica do Robô SCARA Delta com conexão do Controlador com dispositivos periféricos

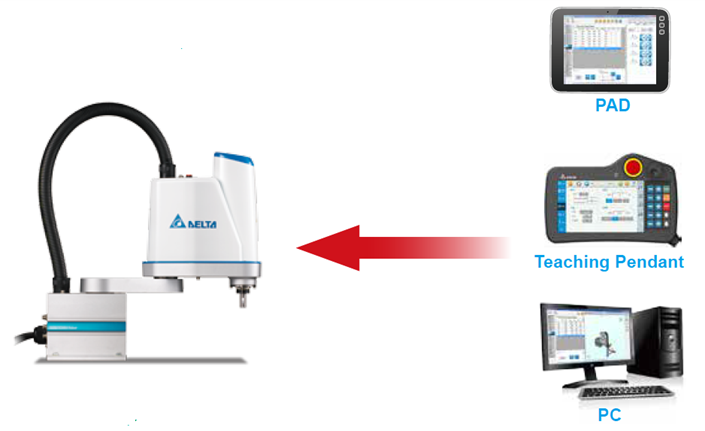

Programação do Robô SCARA: Múltiplos Métodos

A programação do Robô SCARA pode ser feita através de diferentes métodos: Notebook, “Teach Pendant” ou um PAD.

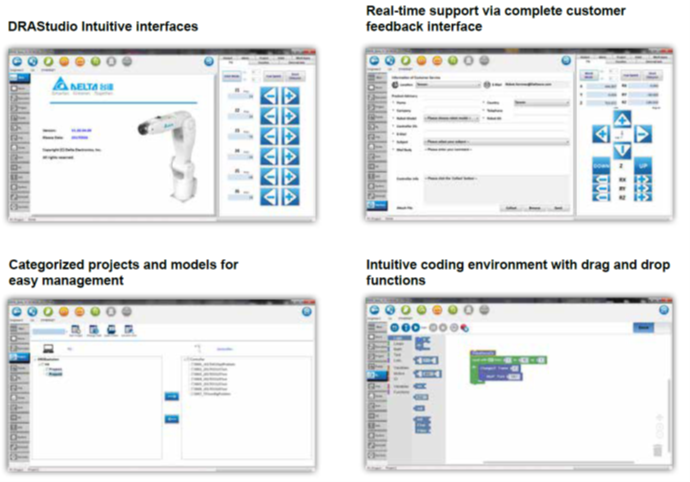

Software de Programação: DRAStudio

DRAStudio é um software para integração robótica, ou seja, possui várias funcionalidades para programação do robô, com linguagens de programação simples e intuitiva, Além disto, possibilita a manutenção do robô através da monitoração em tempo real das suas operações.

- Programação fácil para várias aplicações.

- Cria um ambiente de simulação off-line para robôs.

- Ambiente de programação amigável.

- Programação gráfica rápida e fácil.

- Linguagens de programação simplificadas e comandos simples que possibilitam um ambiente de desenvolvimento eficiente.

- Integra dados e sinais de dispositivos periféricos para configurar interface definida pelo usuário.

Exemplo de Telas do DRAStudio

Handhel Teach Pendant

A programação de um robô com instruções manuais pode ser trabalhoso e requerer muito tempo para depurar o programa. Além disso, é difícil atingir 100 por cento precisão de movimento no espaço 3D. Um método de programação de Robôs é utilizar um dispositivo portátil chamado “Handheld Teach Pendant”, ou Interface Homem Máquina para Robô. O “Handheld Teach Pendant” permite ao operador mover o robô através de uma variedade de movimentos. Quando uma sequência foi totalmente especificada, o robô pode operar a programação a toda velocidade.

Handheld Teach Pendant

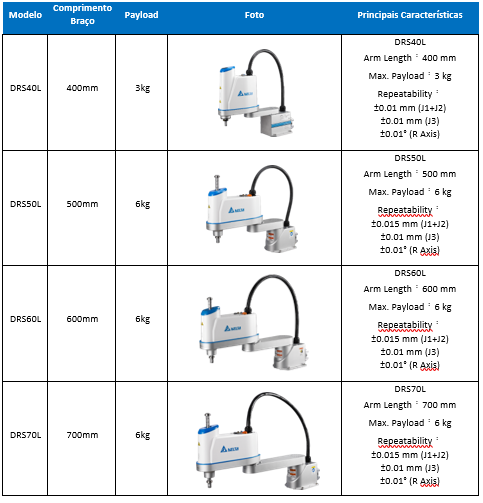

Modelos de Robôs SCARA

Estão disponíveis para comercialização 4 modelos de Robô SCARA Delta, conforme tabela abaixo, que mostra as principais características destes modelos. A escolha do melhor modelo para atender a aplicação do cliente dependerá de duas características principais: o comprimento máximo do braço robótico e do payload (carga máxima suportada pelo robô incluindo a ferramenta instalada).

ROBÔ SCARA 5 EIXOS

O Robô SCARA Delta de 5 Eixos disponível para comercialização é o modelo DRS60L3, cujo comprimento de braço é de 600mm e com Payload de 4kg.

Faça download do material:

Quer saber mais?

Entre em contato com a nossa equipe ou baixe os materiais:

Ficou com alguma dúvida ou precisa de um orçamento?

Preencha os dados abaixo e fale com um de nossos especialistas

Prometemos não utilizar suas informações de contato para enviar qualquer tipo de SPAM.

Produtos Relacionados

Endereço

São José dos Campos

Estrada Velha Rio-São Paulo, 5300

Eugênio de Melo | São José dos Campos

CEP: 12247-004 | SP – Brasil