- +55 (12) 3932-2300

- marketing.br@deltaww.com

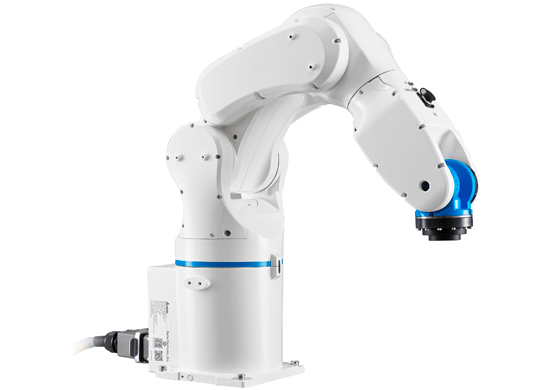

Robô Articulado

- Robôs Industriais

Descrição

Robô Articulado: desenvolvido para aplicações industriais que requeiram Alta Flexibilidade.

Os Robôs Articulados da Delta, Série DRV, com controlador de robô série DCV, facilitam integração perfeita com outros dispositivos periféricos da Delta para estabelecer estações de trabalho robotizadas altamente integradas que permitem excelente eficiência de produção e, além disto, permitem reduzir os custos de mão de obra.

Com excelente flexibilidade, os Robôs Articulados de 6 eixos têm duas faixas de trabalho diferentes para atender a uma ampla variedade de demandas de aplicações. Os robôs podem ser amplamente utilizados em indústrias como como eletrônica, elétrica, processamento de metal, borracha e plásticos, bem como em várias aplicações, incluindo inspeção, montagem, distribuição de cola, manutenção de máquinas, embalagem, solda e carga/descarga. A Série DRV da Delta é sua melhor parceira para atingir o conceito para a Indústria 4.0.

Ficou com alguma dúvida ou precisa de um orçamento?

Preencha os dados abaixo e fale com um de nossos especialistas

Prometemos não utilizar suas informações de contato para enviar qualquer tipo de SPAM.

Produtos Relacionados

Endereço

São José dos Campos

Estrada Velha Rio-São Paulo, 5300

Eugênio de Melo | São José dos Campos

CEP: 12247-004 | SP – Brasil