- +55 (12) 3932-2300

- [email protected]

Cardboard packaging boxes, gift packages and other products made from paper have become essential to our daily lives. They are present in the products we consume, such as groceries, clothing, and educational or entertainment items. They are also applied on different occasions like weddings, holidays and other events. Since the demand for this type of packaging has increased along with the demand for the products we consume on a daily basis, cardboard manufacturers are challenged to provide diverse products to meet customer needs while maintaining high quality standards. of manufacturing. Finished products require compactness, symmetrical quality and uniformity, as well as highly accurate assembly with minimal defect rates. The efficiency and accuracy of a carton production line is often affected by workers taking days off, accidents with injuries or shifting work shifts which lead to poor quality and inconsistent production. To solve these problems and surpass production speed and accuracy levels, packaging manufacturers are starting to upgrade their original manual production lines by applying automation equipment and solutions that increase production flexibility and efficiency and, in addition, can reduce labor and production costs.

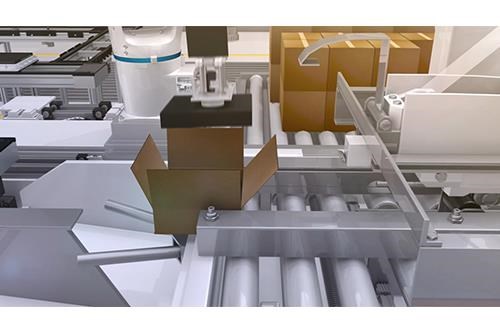

To meet the fast, accurate automatic forming requirements of cardboard manufacturing, Delta recently provided a high-precision, highly efficient and flexible solution for forming cardboard lids for a plant in Mainland China. The automatic forming line guarantees finished products with high quality and, in addition, optimizes production management, while making it possible to reduce labor, production cost and material waste. The line includes five processes: paper feeding, gluing, assembly, pressing and forming. Delta's solution employs the series' 24-axis Motion Controller DVP15-MC to control the conveyors and send the paper, in raw state, to the gluing station with the help of the series vector control frequency inverter C2000 and the series drive system ASDA-A2R . After the paper is glued and sent to the assembly station by the conveyor, the machine's vision system positions the paper using the captured images. At the same time, the modularized Robot Controller program with Integrated Servo Drive of the series ASDA-MS, controls the DRS60L series SCARA robot to take the semi-finished cardboard from the material tray and assemble the cardboard based on the result of the positioning signal. In the end, the conveyor sends the semi-finished and assembled product to the last two stations for high precision pressing and shaping to complete the entire assembly process. The Delta solution for automatic cardboard lid forming has provided our customer with an intelligent, efficient and flexible forming line that combines various intelligent products and modularized programs, allowing easy parameter and control setting and effectively improving production quality and speed.

Considering the needs of this customer, Delta's automatic cardboard cap forming solution adopts the series DVP15-MC 24-axis Motion Controller to optimize manufacturing quality and management effectiveness. With its robust industrial network, the series DVP15-MC Simultaneously connects multiple devices such as AC motor drives, servo drives and motors to realize real-time and accurate control of conveyors for the entire forming line and feeding, gluing and pressing movements. In addition, the Robot Controller, with Integrated Servo Drive from the series ASDA-MS, combines a controller and servo drive in one control unit that increases the control performance of the SCARA robot to pick up cardboard and attach paper, resulting in a perfect movement and successfully reducing defect rates and waste costs.

In this real application, Delta's cardboard lid forming solution brought the following benefits to our customer:

- Real-time data monitoring for easy data management and analysis: Delta's cardboard lid forming solution uses the series Motion Controller DVP15-MC 24-axis that is integrated with a variety of industrial network communication ports (eg Ethernet, RS-232 and RS-485). You can instantly connect and control 3 sets of the series vector control frequency inverter C2000, 5 sets of series drive system ASDA-A2R and a 7-inch Widescreen HMI DOP-B series operator interface (via Ethernet), providing real-time adjustment of conveyor motor speed for multi-function control and high-precision performance. In addition, the DVP15-MC series is capable of storing a variety of production data including production counts and yield to reduce material waste and improve production management and analysis.

- High precision intelligent equipment to optimize production quality and efficiency: With the stable performance of the SCARA Robot from the series DRS60L and with the high precision positioning algorithm of the Series Machine Vision System DMV 2000, the system quickly calculates the special characteristics of each semi-finished cardboard, achieving high reproducibility and minimizing production error rates. The efficient operation of the series DRS60L and DMV 2000 they are also able to solve the human error of the traditional manual forming line, reducing labor cost and optimizing production quality. The built-in easy calibration function speeds up overall processing efficiency, allowing users to simply enter parameters to complete the coordinate setup of the Machine Vision System and SCARA Robot.

- Flexible and fast production with simple setup and programming: in this solution we have the series modular programming software PVS100 with an operating process guide and easy system operating interfaces that facilitate configuration and control of peripheral equipment, such as the Robot Controller, with Series Integrated Servo Drive ASDA-MS, Machine Vision System and more, achieving speed and convenient operation. Users can simply enter parameters to automatically change the production mode, creating a highly flexible production line. Our solution not only improves manufacturing quality and efficiency with real-time data analysis, but also creates a flexible and diversified production management system to ensure competitiveness and a better future.

Delta's Cardboard Lid Forming Solution provides a high precision, high efficiency and flexibility cardboard forming line that improves the quality and effectiveness of production, meeting customer requirements.

Delta's 24-axis Motion Controller DVP15-MC series is capable of connecting various devices (eg AC motor drives, servo drives, HMI) and storing various production data to improve production management and analysis .

Delta Robot Controller, with Integrated Servo Drive of the ASDA-MS series, is a highly integrated control system that allows controlling the SCARA robot performance in the formation of cardboard lids quickly and accurately.

With a simple setup, Delta's DRS60L series SCARA Robot is able to perform stable movements that accurately complete the cardboard assembly process, optimizing production quality.

Fill out the form and receive our updates directly to your email

Address

São José dos Campos

Estrada Velha Rio-São Paulo, 5300

Eugênio de Melo | São José dos Campos

CEP: 12247-004 | SP - Brazil