- +55 (12) 3932-2300

- [email protected]

Introduction

The “Control Block” is one of the most used functions in the development of HMI Delta. With this function, the user can define writing and reading variables to use as required by the project.

To access the control area of the “Control Block” it is simple and easy:

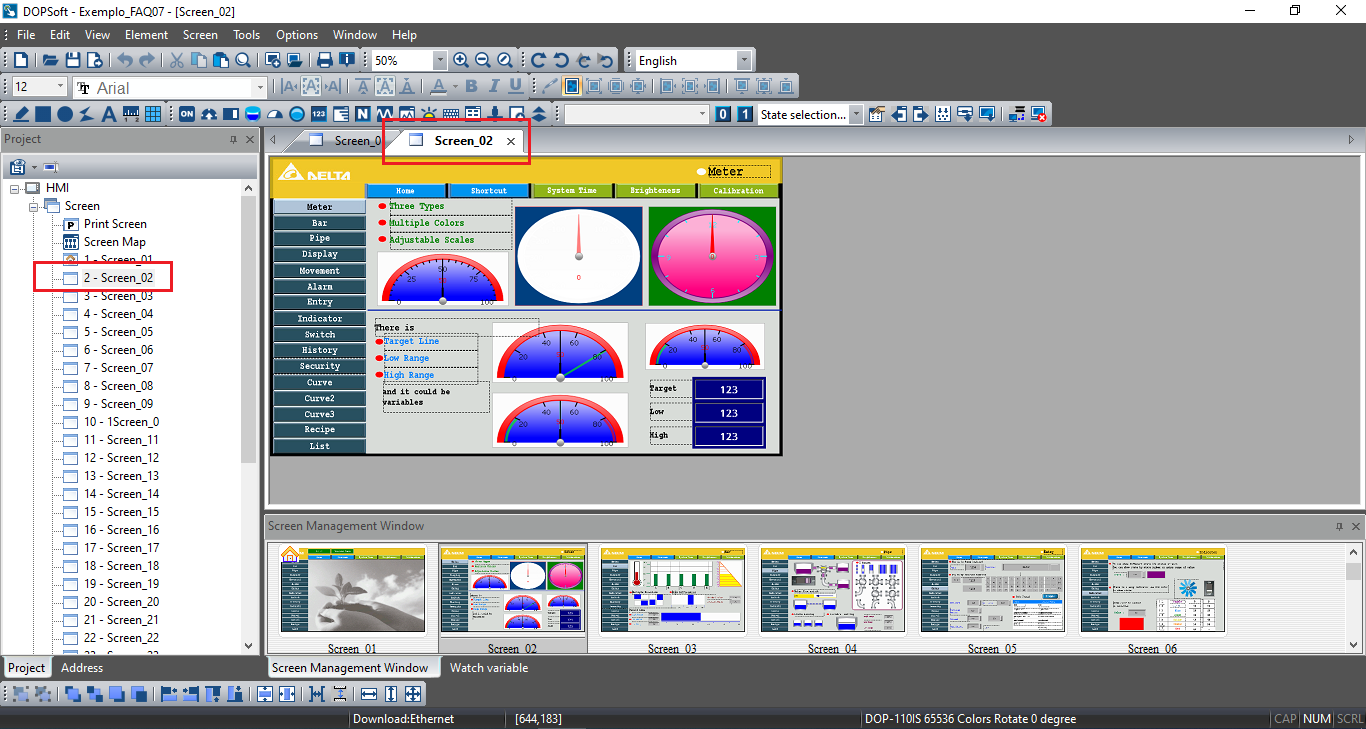

1.In the DOPSoft access bar, access the “Options' menu:

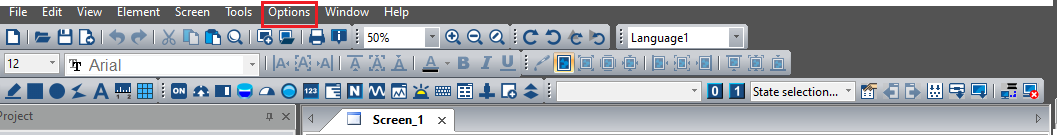

2. Within the options menu, select “Configuration”

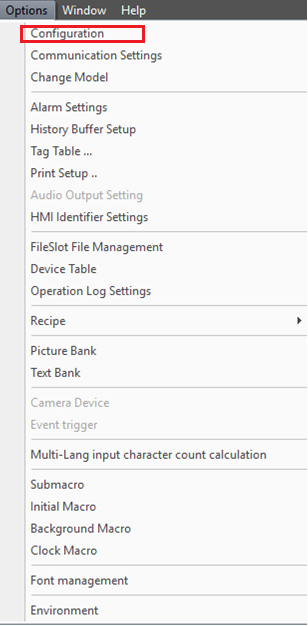

3.Select the “Control Block” option in the settings menu on the left.

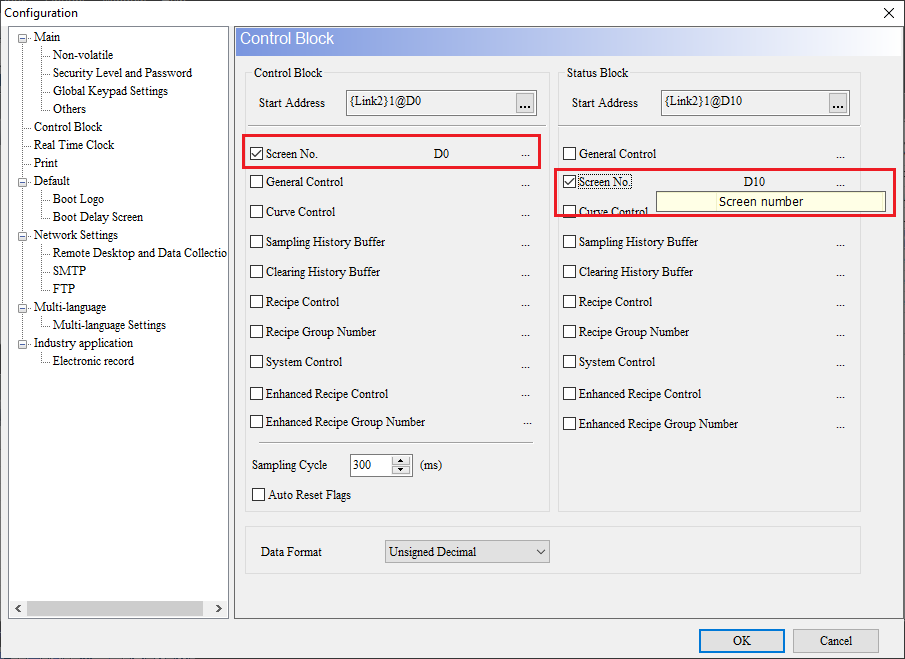

DOPSoft allows the user to use addresses / configuration variables for writing data in the “Control Block” option or reading data in the “Status Block”.

These variables can make screen changes or indicate which current screen on the HMI during the operation, even define recipe variables, clear historical data, among other functions that can be defined using the “Control Block” and “Status Block”.

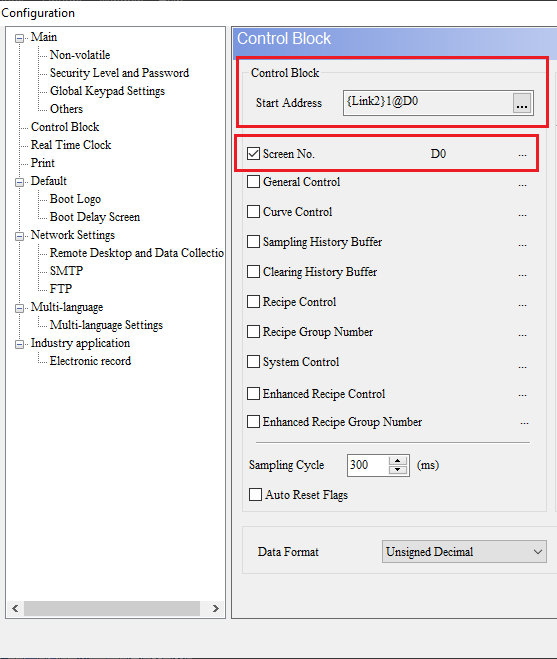

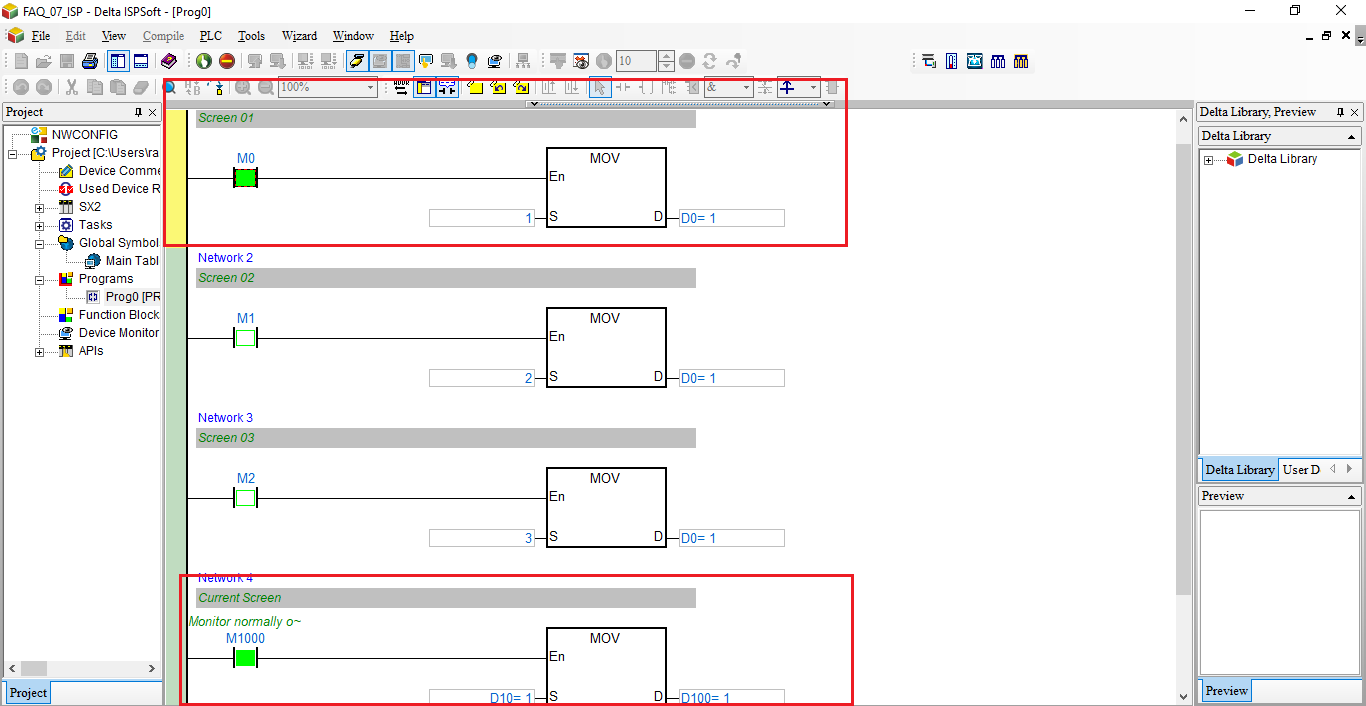

The example below indicates the use of the external variable D0 to control the selection of screens. When defining a writing value for this variable inserted in the option “Screen NO”, in the tab “Control Block”. The HMI will change the screen for the value assigned to this variable.

- Variable configuration D0 - Control Block for changing screens on the HMI

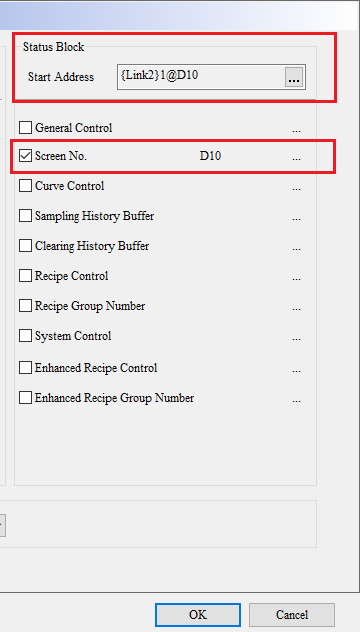

To visualize the current screen on the HMI, variable D10 was declared in the “Screen NO” of the “Status Block” tab, as the screens on the HMI change, the value of this variable changes.

2. Setting of variable D10 - Status Block indicates the current screen value.

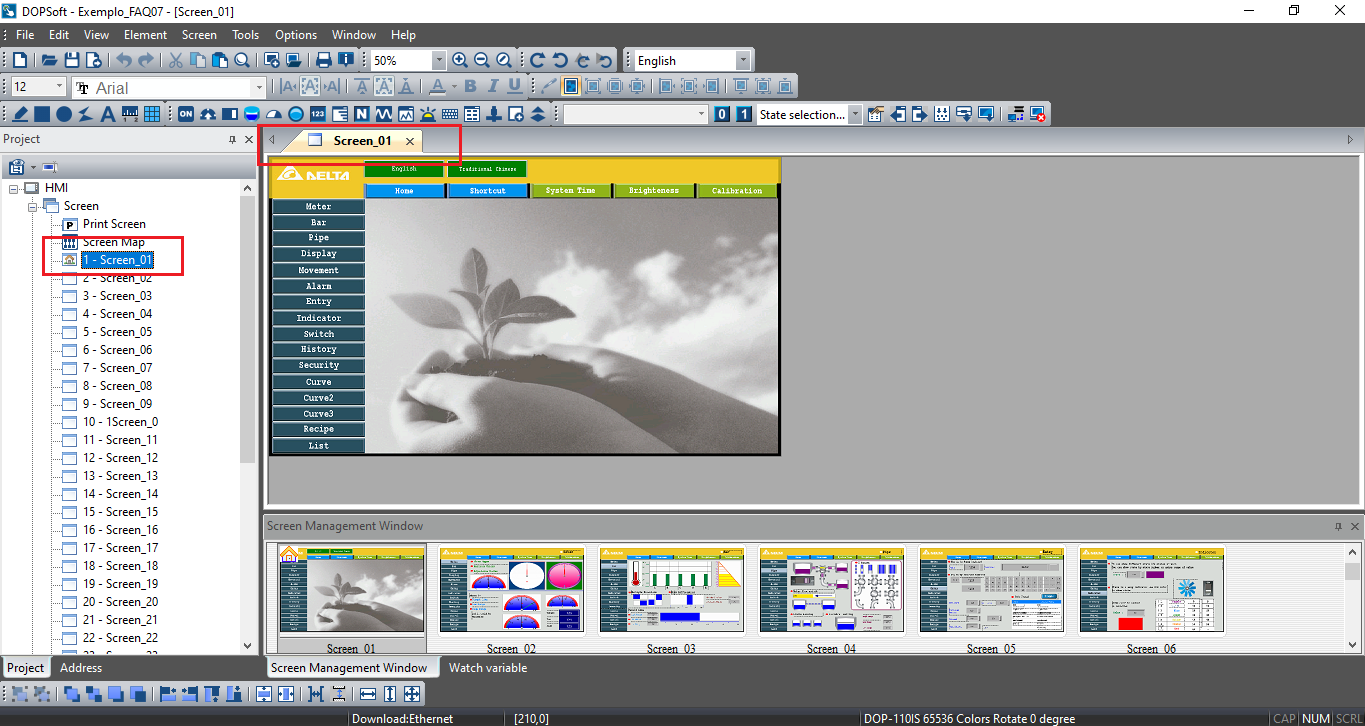

3. Visualization of Screen 01 in DOPSoft, indication of the home screen.

4. In the program it indicates the value inserted in the variable D0 = 1 where it will make the control of the screen that will be visualized in the HMI. The display on variable D10 indicates the current screen.

5. Display on the HMI of Screen 01 according to the value entered in variable D0.

6.DOPSoft view of configuration screens